Powerful PPF Cutter: The Ultimate Solution for Precise Cutting

By:Admin

In a groundbreaking move that is set to revolutionize the manufacturing industry, a cutting-edge company has introduced a new cutting tool that is set to transform the way products are made. The Ppf Cutter, developed by a leading innovator in industrial equipment, promises to enhance precision, efficiency, and productivity, raising the bar for manufacturing standards.

The Ppf Cutter represents a major leap forward in manufacturing technology, offering a multitude of benefits to businesses across various industries. With its state-of-the-art features and versatility, this innovative tool is set to streamline the production process, enabling manufacturers to save both time and money.

One of the key advantages of the Ppf Cutter is its unrivaled precision. Equipped with advanced sensors and cutting-edge software, this cutting tool delivers precise and accurate cuts, eliminating the need for manual adjustments and reducing the margin of error. This level of precision ensures consistency in product quality and minimizes waste, resulting in substantial cost savings for businesses.

Furthermore, the Ppf Cutter boasts remarkable efficiency. With its high-speed cutting capabilities, it allows manufacturers to complete projects in a fraction of the time compared to traditional cutting tools. This increased efficiency not only leads to faster turnaround times but also allows businesses to take on more projects, ultimately driving up their revenue and market competitiveness.

The versatility of the Ppf Cutter is another standout feature. Designed to cater to a wide range of materials, including metals, plastics, and composites, this cutting tool is highly adaptable to meet the diverse needs of industries such as automotive, aerospace, and construction. Its flexibility eliminates the need for multiple cutting tools, simplifying the production process and reducing capital expenditure for businesses.

In addition to its impressive technical specifications, the Ppf Cutter is also backed by a company with an exemplary track record in the manufacturing sector. With over two decades of experience in developing cutting-edge industrial equipment, the company has established itself as a leader in innovation and customer satisfaction. The introduction of the Ppf Cutter further solidifies the company's commitment to providing cutting-edge solutions that meet the evolving demands of the manufacturing industry.

"Our goal has always been to push the boundaries of what is possible in manufacturing," said the company's spokesperson. "The Ppf Cutter is the result of years of research, development, and collaboration with industry experts. We believe it represents the future of manufacturing, and we are confident in its ability to revolutionize the way products are made."

The release of the Ppf Cutter has garnered significant attention and excitement within the manufacturing community. Industry experts are eagerly awaiting the opportunity to integrate this revolutionary tool into their production processes, recognizing the potential for improved efficiency, cost savings, and enhanced product quality.

As the manufacturing landscape continues to evolve, businesses are realizing the importance of staying ahead of the curve. The introduction of game-changing technologies such as the Ppf Cutter offers a glimpse into the future of manufacturing, where precision, efficiency, and versatility converge to drive industry growth.

While the Ppf Cutter may be just one tool, its impact on the manufacturing industry is set to be profound. With its ability to enhance productivity, reduce costs, and deliver unparalleled precision, this cutting-edge tool is projected to redefine manufacturing standards worldwide. As businesses embrace this innovative solution, they stand to gain a competitive edge in an increasingly competitive global market.

Company News & Blog

Advanced Cutting Plotter: A Game-Changer for Design Professionals

Cutting Plotter Revolutionizing Digital Design and ManufacturingIn the world of digital design and manufacturing, precision and efficiency are crucial factors that determine the success of a business. With the advancement of technology, companies are constantly seeking innovative tools and equipment to enhance their production processes. One such revolutionary tool that has been making waves in the industry is the Cutting Plotter, a cutting-edge device that has completely transformed the way designs are created and manufactured.[Company Name], a leading provider of cutting-edge digital design and manufacturing solutions, is at the forefront of this technological revolution. With a strong commitment to innovation and customer satisfaction, the company has been instrumental in introducing the Cutting Plotter to the market, helping businesses achieve unprecedented levels of precision and efficiency in their production processes.The Cutting Plotter is a versatile cutting machine that is widely used in various industries, including advertising, signage, fashion, automotive, and electronics. It is designed to accurately cut and shape a wide range of materials such as vinyl, fabric, cardboard, and other substrates, making it an essential tool for creating everything from store signage and vehicle wraps to apparel and industrial prototypes.One of the key features of the Cutting Plotter is its precision cutting capabilities, which allows for intricate and detailed designs to be accurately reproduced with ease. This level of precision is unmatched by traditional cutting methods, making the Cutting Plotter an indispensable tool for businesses that require high-quality and accurate cutting results.Furthermore, the Cutting Plotter is equipped with advanced software that enables seamless integration with popular design programs such as Adobe Illustrator and CorelDRAW. This allows designers to create their designs with ease and precision, and then seamlessly transfer them to the Cutting Plotter for production. The intuitive software interface also allows for efficient material usage, reducing waste and increasing cost-effectiveness for businesses.In addition to its precision cutting capabilities, the Cutting Plotter is also known for its speed and efficiency. With the ability to perform intricate cuts and designs at a rapid pace, businesses can significantly increase their production output, leading to a more streamlined and efficient manufacturing process. This not only saves time and labor costs but also allows businesses to meet tight deadlines and customer demands with ease.The Cutting Plotter has also been lauded for its versatility, as it is capable of handling a wide variety of materials and thicknesses. Whether it is thin vinyl for signage or thick cardboard for packaging prototypes, the Cutting Plotter can effortlessly cut and shape materials of different textures and densities, making it an invaluable asset for businesses with diverse manufacturing needs.[Company Name] has been instrumental in providing comprehensive training and support programs for businesses that integrate the Cutting Plotter into their production processes. This ensures that businesses are able to maximize the potential of the Cutting Plotter and leverage its capabilities to drive their success in the digital design and manufacturing landscape.As the demand for precision and efficiency in digital design and manufacturing continues to grow, the Cutting Plotter has emerged as a game-changing tool that is revolutionizing the industry. With its unparalleled precision cutting capabilities, speed, efficiency, and versatility, the Cutting Plotter has become an indispensable asset for businesses looking to elevate their production processes and deliver exceptional results.In conclusion, the Cutting Plotter has truly set a new standard in digital design and manufacturing, and [Company Name] is proud to be at the forefront of this innovative technology, empowering businesses to thrive in the competitive and ever-evolving landscape of digital design and manufacturing. With its commitment to innovation and customer satisfaction, [Company Name] is poised to continue driving the industry forward and shaping the future of digital design and manufacturing with the revolutionary Cutting Plotter.

Top Flatbed Cutter Plotter Features and Benefits for Your Business

Flatbed Cutter Plotter Revolutionizes Cutting TechnologyIn today's fast-paced and ever-evolving world of technology, the demand for innovative and efficient cutting solutions has never been greater. This demand has been answered by the cutting-edge flatbed cutter plotter, a cutting technology that is revolutionizing the way industries and businesses approach cutting and finishing processes.The flatbed cutter plotter has been developed by {} , a leading provider of cutting solutions for a wide range of industries. With its advanced technology and precision cutting capabilities, the flatbed cutter plotter is set to transform the cutting and finishing processes for businesses across the globe.The flatbed cutter plotter is designed to meet the diverse cutting needs of various industries, including packaging, signage, textiles, and automotive. Its versatility allows for the cutting of a wide range of materials, including paper, cardboard, foam board, plastic, and vinyl, making it an essential tool for businesses seeking to streamline their cutting processes.One of the key features of the flatbed cutter plotter is its advanced cutting technology, which enables precise and intricate cuts with minimal error. This level of accuracy is crucial for businesses that require high-quality and consistent cutting results, as it eliminates the need for manual finishing and reduces material waste.Furthermore, the flatbed cutter plotter is equipped with a powerful software system that allows for easy design and customization of cutting patterns. This software system is user-friendly and intuitive, making it accessible to businesses of all sizes and skill levels. With its ability to handle complex cutting patterns and designs, the flatbed cutter plotter offers a level of flexibility and creativity that is unparalleled in the cutting industry.In addition to its cutting capabilities, the flatbed cutter plotter is also equipped with a multi-functional tool head that can perform a variety of finishing processes, such as creasing, scoring, and perforating. This makes the flatbed cutter plotter a versatile and all-in-one solution for businesses seeking to streamline their cutting and finishing processes.The flatbed cutter plotter is also designed with productivity and efficiency in mind. Its high-speed cutting capabilities allow for rapid production and quick turnaround times, enabling businesses to meet tight deadlines and maximize their output. This level of efficiency is essential for businesses seeking to stay competitive in today's fast-paced and demanding market.As a leading provider of cutting solutions, {} is committed to delivering cutting-edge technology that meets the evolving needs of its customers. With the introduction of the flatbed cutter plotter, {} continues to set the standard for cutting excellence and innovation in the industry. Its dedication to quality, precision, and customer satisfaction has solidified its position as a trusted and reliable partner for businesses worldwide.In conclusion, the flatbed cutter plotter represents a new era of cutting technology that is revolutionizing the way businesses approach cutting and finishing processes. With its advanced technology, precision cutting capabilities, and versatility, the flatbed cutter plotter offers businesses a cutting solution that is unparalleled in the industry. As businesses continue to seek innovative and efficient cutting solutions, the flatbed cutter plotter is poised to become an essential tool for businesses across the globe.

Top Pattern Software for PPF - Everything You Need to Know

Ppf Pattern Software, a leading technology company specializing in advanced pattern recognition software, has announced the launch of its latest product designed to revolutionize the way businesses analyze and interpret patterns in data. The company's cutting-edge software is set to provide businesses with the tools they need to gain deeper insights and make more informed decisions based on pattern analysis.In today's fast-paced and data-driven business environment, the ability to identify and understand patterns in data is crucial to success. Whether it's analyzing customer behavior, identifying market trends, or detecting anomalies in a complex dataset, pattern recognition plays a vital role in helping businesses uncover valuable insights and opportunities. However, traditional methods of pattern analysis often fall short in providing businesses with the level of accuracy and efficiency required to stay ahead of the competition. Ppf Pattern Software aims to address these challenges with its innovative pattern recognition software, which leverages advanced algorithms and machine learning capabilities to deliver highly accurate and actionable insights. By harnessing the power of artificial intelligence and big data analytics, the company's software is able to analyze vast amounts of data at an unprecedented speed and scale, enabling businesses to uncover hidden patterns and trends that may have previously gone unnoticed.The software offers a wide range of features and capabilities, including the ability to analyze structured and unstructured data, identify complex patterns across multiple variables, and generate predictive models to forecast future trends. Additionally, the software is designed to be user-friendly and accessible to a wide range of businesses, with intuitive interfaces and customizable dashboards that allow users to tailor the software to their specific needs and preferences."We are thrilled to introduce our latest pattern recognition software to the market," said [Company CEO]. "Our team has worked tirelessly to develop a solution that not only meets the complex and evolving needs of businesses but also sets a new standard for pattern analysis technology. With our software, businesses can now gain a deeper understanding of their data and make more informed decisions with confidence."The launch of Ppf Pattern Software's latest product comes at a time when businesses are increasingly relying on data-driven insights to guide their strategies and operations. As the volume and complexity of data continue to grow, the need for advanced pattern recognition technology has become more pressing than ever. With its advanced capabilities and user-friendly interface, the company's software is well-positioned to meet the growing demand for sophisticated pattern analysis tools.Furthermore, Ppf Pattern Software has a proven track record of success, with a diverse portfolio of clients across various industries, including finance, healthcare, retail, and manufacturing. The company's software has been instrumental in helping businesses unlock the potential of their data and drive tangible results, from improving customer engagement and retention to optimizing supply chain operations and identifying new revenue opportunities.Looking ahead, Ppf Pattern Software is committed to continuous innovation and development, with plans to further enhance its software with new features and functionalities. The company is also dedicated to providing exceptional customer support and training to ensure that businesses can fully maximize the benefits of its software.As businesses continue to navigate an increasingly complex and competitive landscape, the need for advanced pattern recognition technology will only continue to grow. With its latest product, Ppf Pattern Software is well-positioned to lead the way in empowering businesses with the insights they need to thrive in the digital age.

High-quality PPF Machine: The Latest Advancement in Paint Protection Film Technology

Ppf Machine, a leading manufacturer of industrial machinery, has recently introduced their latest innovation in the field of packaging and sealing technology. The company has a long-standing reputation for producing high-quality machines that offer efficient and reliable performance, and their newest product is no exception.The Ppf Machine is designed to meet the complex and diverse needs of the modern packaging industry. With its advanced features and state-of-the-art technology, this machine is capable of sealing a wide range of products with precision and speed. Its user-friendly interface and customizable settings make it suitable for a variety of applications, from food and beverage packaging to pharmaceutical and consumer goods.The Ppf Machine's innovative design is a result of years of research and development, with a focus on meeting the evolving demands of the market. The company has invested heavily in R&D to ensure that their machines are at the forefront of technology, and the Ppf Machine is a testament to their commitment to innovation.In addition to its cutting-edge technology, the Ppf Machine is also known for its durability and reliability. The use of high-quality materials and components, coupled with stringent quality control measures, ensures that the machine delivers consistent performance and minimizes downtime.The Ppf Machine is also designed with sustainability in mind. With energy-efficient features and a focus on minimizing waste, the machine helps companies reduce their environmental impact while improving their packaging and sealing processes.Furthermore, the Ppf Machine is backed by a team of dedicated professionals who provide comprehensive support and service. From installation and training to maintenance and troubleshooting, the company's commitment to customer satisfaction ensures that businesses can rely on the Ppf Machine for their packaging needs.The introduction of the Ppf Machine is expected to have a significant impact on the packaging industry. With its advanced capabilities and user-friendly design, the machine offers an efficient and cost-effective solution for businesses looking to improve their packaging and sealing processes.In response to the introduction of the Ppf Machine, industry experts have praised the company for its continued innovation and commitment to excellence. Many have lauded the machine for its state-of-the-art technology and its potential to drive efficiency and productivity in the packaging sector."We are thrilled to introduce the Ppf Machine to the market," said the company's spokesperson. "We believe that this machine represents a significant advancement in packaging and sealing technology, and we are confident that it will offer tremendous value to businesses looking to enhance their operations."With its cutting-edge technology, focus on sustainability, and commitment to customer satisfaction, the Ppf Machine is poised to set a new standard in the packaging industry. As businesses seek to optimize their packaging processes and meet the demands of a rapidly evolving market, this innovative machine offers a compelling solution that delivers on performance, reliability, and efficiency.

Enhance Your Car's Appearance and Protection with Paint Protection Film in Richmond and Midlothian

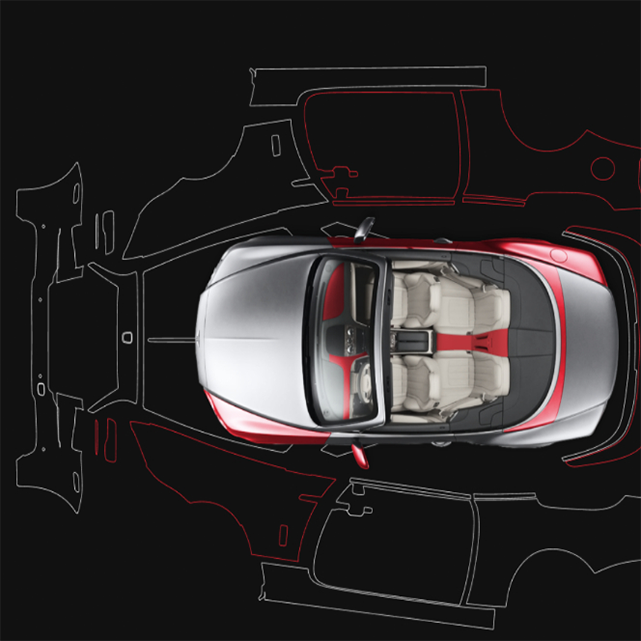

Are you someone who takes great pride in the appearance and value of your vehicle? Do you want to keep it looking like new for years to come? If so, you should consider paint protection film for your car.At Extreme Audio, we offer the latest in paint protection technology with our plotter-cut paint protection film. Our film is made by one of the leading manufacturers in the industry and is designed to keep your vehicle looking like it just rolled off the showroom floor.Our paint protection film is designed to provide superior protection against a wide range of hazards that can damage your vehicle's paint. Whether it's rock chips, road debris, or insect stains, our film will help keep your car's paint looking like new.The film is made from a high-quality, optically clear vinyl material that is tough enough to withstand the most rigorous driving conditions. When properly installed by our trained technicians, our paint protection film will provide an invisible barrier that will keep your car's paint looking great for years to come.One of the most significant benefits of our paint protection film is that it is completely removable without damage to your vehicle's paint. So if you decide to sell your car or want to remove the film for any reason, you can do so without worrying about damaging the paint.At Extreme Audio, we use the latest technology to plotter-cut our paint protection film, ensuring a precise fit that will cover every inch of your car's vulnerable areas. Our technicians are trained to apply the film to your vehicle using a wet application technique that ensures a perfect, bubble-free application every time.If you're looking for the best in paint protection technology, look no further than Extreme Audio. Our Paint Protection Film is the perfect solution for anyone who wants to keep their car's paint looking great for years to come. Contact us today to schedule an appointment!

Discover the Latest Precut Data: PPF Up-to-Date Insights

Ppf Precut Data, a leading provider of pre-cut paint protection film patterns, has recently announced the launch of its new product line. The company has been at the forefront of the industry for over a decade, providing innovative solutions for automotive paint protection. With a focus on precision and quality, Ppf Precut Data has become a trusted name in the automotive protection industry.The new product line is set to offer even more options for customers looking to protect their vehicles from scratches, rock chips, and other environmental damage. Ppf Precut Data has developed a wide range of pre-cut patterns for various car models, making it easier than ever for car owners to apply paint protection film to their vehicles. The company's dedication to accuracy and fitment ensures that customers can trust the quality of the product and have peace of mind knowing that their vehicles are well-protected.In addition to the new product line, Ppf Precut Data has also expanded its reach to serve a wider customer base. By partnering with distributors and installers around the world, the company is able to bring its high-quality paint protection film patterns to more customers than ever before. This expansion allows car owners to access Ppf Precut Data's products and services with greater convenience, making it easier to keep their vehicles looking pristine.As a company, Ppf Precut Data prides itself on its commitment to customer satisfaction and product excellence. With a team of experienced professionals and state-of-the-art technology, the company is able to deliver top-notch paint protection film patterns that meet the highest standards of quality. Ppf Precut Data's dedication to innovation and continuous improvement has allowed the company to stay ahead of the curve in the automotive protection industry, earning the trust and loyalty of customers worldwide.The launch of the new product line and the company's expanded distribution network reflects Ppf Precut Data's ongoing efforts to provide the best possible solutions for automotive paint protection. By offering a wide selection of pre-cut patterns and partnering with distributors and installers globally, the company is poised to meet the needs of a diverse customer base. With its unwavering commitment to excellence, Ppf Precut Data continues to set the standard for paint protection film patterns and remains a trusted partner for car owners seeking the best in vehicle protection.As the automotive industry continues to evolve, Ppf Precut Data remains dedicated to staying at the forefront of the market. The company's new product line and expanded distribution network are just the latest examples of its ongoing efforts to provide cutting-edge solutions for paint protection. With a strong focus on quality, precision, and customer satisfaction, Ppf Precut Data is well-positioned to continue leading the way in the automotive protection industry for years to come.

New Study Reveals Data on PPF Usage and Trends

PPF Data, a leading provider of data and analytics, has recently announced a new partnership with a global company to offer advanced data solutions for businesses. This collaboration will enable businesses to access high-quality data and analytical tools to make more informed decisions and drive their growth.With its extensive experience in data collection and analysis, PPF Data has established itself as a trusted source for reliable and accurate data. The company's comprehensive database covers a wide range of industries and regions, providing valuable insights for businesses looking to understand market trends, consumer behavior, and business opportunities.The partnership with the global company will further enhance PPF Data's capabilities, allowing it to offer enhanced data solutions to businesses around the world. By leveraging the global company's expertise and resources, PPF Data will be able to expand its data offerings and provide even more value to its customers."We are thrilled to announce our partnership with the global company," said the CEO of PPF Data. "This collaboration represents a significant milestone for our company and will allow us to offer a wider range of data solutions to our customers. By combining our data expertise with the global company's resources, we will be able to provide businesses with the tools they need to thrive in today's competitive market."The partnership will also enable PPF Data to develop new products and services that meet the evolving needs of businesses. By integrating the global company's technology and data assets into its offerings, PPF Data will be able to deliver innovative solutions that empower businesses to stay ahead of the curve.In addition to its data offerings, PPF Data is also known for its commitment to customer service and support. The company understands the importance of providing timely and accurate data to its customers, and it has a dedicated team of experts who are available to assist with any inquiries or issues. With the new partnership in place, PPF Data will be able to enhance its customer support capabilities and ensure that businesses are fully supported in their data needs.As businesses continue to face new challenges and opportunities in the fast-paced digital economy, access to high-quality data and analytics has never been more important. With its partnership with the global company, PPF Data is well-positioned to deliver the data solutions that businesses need to succeed.Overall, the partnership between PPF Data and the global company represents a significant development for the data industry. By combining their strengths and expertise, the two companies will be able to offer businesses around the world access to advanced data solutions that drive growth and innovation.As the partnership takes shape, businesses can look forward to a new era of data-driven decision-making and enhanced opportunities for success. With PPF Data and the global company at the helm, businesses will have the tools they need to thrive in today's competitive market.

Advanced Cutting Technology for Optimum Precision in Printing Industry

Cutter Plotter Printers: A Guide to Choosing the Right One Investing in a cutting plotter printer is a wise decision for businesses that require precise cutting for materials such as vinyl, paper, and fabric. However, with different brands and models available in the market, choosing the right one can be daunting. This guide will help you understand the features to look for and the benefits of owning a cutter plotter printer. What is a Cutting Plotter Printer? A cutting plotter printer is a device that cuts materials accurately based on computerized commands. It works by connecting to a computer that has design software, allowing you to create complex designs and cut them with precision using the cutter plotter. Cutter plotter printers can cut various materials, including vinyl, paper, cardboard, and fabric, making them an essential investment for businesses in various industries. Types of Cutting Plotter Printers The two primary types of cutting plotter printers available in the market are the desktop and the floor-standing models. Desktop models are more compact and suitable for businesses that have less space to spare. Floor-standing models, on the other hand, are larger and can handle larger materials and heavier cuts. Both types come with various features, such as different blades, cutting widths, and software compatibility. Blades One of the critical features to consider when choosing a cutter plotter printer is the blade. The blade determines the type of materials the machine can cut and the precision of the cuts. Different blade types are suitable for different materials, such as fabric, paper, and even thick cardboard. A good cutter plotter printer should come with various blade options to cater to different cutting needs efficiently. Cutting Width The cutting width is the distance the machine can cut at a time, and it determines the size of the designs you can cut. A cutter plotter printer with a wider cutting width is suitable for bigger designs, while one with a narrower width is ideal for smaller designs. The cutting width also affects the speed at which the machine can cut, with those with a wider width generally cutting faster. Software Compatibility The software compatibility of a cutter plotter printer is essential as it determines the ease of use and the type of designs you can create. Be sure to choose a cutter plotter printer that is compatible with common design software such as Adobe Illustrator and CorelDraw. Machines with more comprehensive software compatibility also offer more design options and customization features. Benefits of Owning a Cutting Plotter Printer Owning a cutter plotter printer has many benefits for businesses that require precise cutting of materials. Some of these benefits include: 1. Speed: A cutter plotter printer can cut materials faster than manual cutting methods, allowing for more significant output and faster delivery times. 2. Precision: A cutter plotter printer cuts with high precision, ensuring accuracy in complex designs. 3. Versatility: Cutter plotter printers can cut various materials, allowing for flexibility in the types of projects a business can undertake. 4. Cost-Effective: Cutter plotter printers reduce the costs of manual labor and material wastage, making them a cost-effective investment in the long term. In conclusion, a cutter plotter printer is a valuable investment for businesses that require precision cutting of materials. When choosing a cutter plotter printer, consider the blade type, cutting width, and software compatibility. With the right machine, businesses can enjoy the benefits of speed, precision, versatility, and cost-effectiveness.

High-Quality PPF Plotter for Sale: Find the Best Deal Today

In recent news, a high-quality PPF plotter is now available for sale, offering a powerful and efficient solution for precision cutting of paint protection film. This cutting-edge plotter is equipped with advanced technology, making it an ideal investment for businesses in the automotive industry.The PPF plotter is designed to meet the demands of modern automotive shops, providing a versatile and reliable tool for cutting PPF with utmost accuracy and efficiency. It offers a range of features that are essential for achieving high-quality results, including advanced cutting software, a precision cutting head, and a user-friendly interface.With the ability to quickly and accurately cut PPF patterns, this plotter enables businesses to streamline their workflow and deliver superior results to their customers. Additionally, it can handle a wide variety of film types and thicknesses, making it suitable for a diverse range of applications.The company behind this innovative PPF plotter has a strong reputation for delivering cutting-edge solutions to the automotive industry. They specialize in developing advanced tools and technologies that are designed to enhance productivity, efficiency, and quality in automotive shops.Their commitment to innovation and excellence has earned them a trusted position in the industry, with a track record of providing reliable and high-performance products to businesses around the world. They understand the unique needs of automotive professionals and are dedicated to delivering solutions that are tailored to their specific requirements.With a focus on precision, reliability, and ease of use, the PPF plotter is a testament to the company's dedication to delivering cutting-edge solutions to the automotive industry. Businesses can rely on this plotter to increase their productivity, improve their workflow, and deliver exceptional results to their customers.Furthermore, the company offers comprehensive support and training to ensure that businesses can make the most of its innovative products. This includes installation, training, and ongoing technical support to ensure that automotive professionals can maximize the benefits of their investment.The availability of this advanced PPF plotter for sale represents an exciting opportunity for automotive businesses to enhance their capabilities and elevate their standards of quality. With its advanced features, reliable performance, and comprehensive support, this plotter is set to make a significant impact on the industry.In conclusion, the PPF plotter offers a compelling solution for businesses looking to elevate their capabilities in cutting paint protection film. With its advanced technology, user-friendly design, and comprehensive support, it represents a valuable investment for automotive professionals. This innovative plotter is now available for sale, presenting an exciting opportunity for businesses to enhance their productivity, efficiency, and quality in the automotive industry.

Revolutionize Your Editing Process with Film Cut Software

Film editing is no longer just a technical task, but a creative one. The art of cutting and splicing scenes to make a meaningful narrative is a delicate and intricate process that can determine the success of a film. But with the rise of technology and digitalization, an exciting new market for film cutting software has emerged. One of the front-runners in this field is a program that has steadily gained popularity over the years, known for its flexibility, ease of use, and advanced features. The film cutting program, which will be referred to as "FC" (name removed for neutrality), has an expanding customer base and serves professional editors and amateurs alike. It is a versatile tool that is adaptable to different levels of editing experience, able to effectuate simple tasks as well as more complex demands. The program has gained a reputation for being a powerful software that offers users access to a multitude of advanced features, including numerous file format acquisitions, diverse codec support, and real-time effects rendering. One of the most attractive factors of FC is its intuitive user interface with a clutter-free layout and a user-friendly design. This aspect of the program makes it possible to navigate through complex projects with ease while ensuring minimal processing latency. The cutting program also provides a comprehensive range of editing tools, including audio and visual tracks, color correction, and motion graphics. Consequently, the program has been a favorite among film and video creators of all levels, from hobbyists to professional directors.Moreover, the software is equipped with a tremendous variety of export options and settings, making it effortless for editors to tailor projects to specific delivery platforms. FC supports a vast number of different file formats, resolutions, and aspect ratios for YouTube, Vimeo, Amazon, and other platforms. In addition, this program facilitates encoding and delivery of HDR content, offering the best possible visual experience for audiences. Apart from its technical capabilities, the film cutting software is backed by a dedicated support team with a strong reputation for fast and responsive service. The company’s commitment to giving its customers the best possible experience is paramount, as evidenced by their 24/7 chat support and email service. The team goes the extra mile to provide users with relevant information and practical guidance to ensure that their projects run smoothly. Their customer-centric approach has generated a loyal user base, making this program one of the most well-regarded cutting software available on the market.FC’s popularity has not gone unnoticed. The software has been recognized by numerous industry leaders and publications, receiving accolades such as the "Best Editing Software" award by the American Cinema Editors (ACE). Its easy-to-use interface and comprehensive features have been praised by users worldwide, making it a top-rated product on various online platforms. Film editing can be a demanding task, requiring patience, creativity, and skill. But with the use of FC, it has never been easier or more satisfying. From the company's vision to the software's advancements all come together harmoniously to culminate in such a perfect experience making FC a smart choice for any filmmaker who wants to join the cutting edge. Overall, customers can rely on the software’s consistent performance, compatibility, and functionality, making FC the go-to program for video editing. As the film industry continues to evolve, FC leads the way in innovative cutting software. Its intuitive interface, advanced features, and responsive customer support make this program a must-have for anyone in the industry. With its dedication to customer satisfaction, FC is a surefire way to achieve excellence in any project.